The Michigan-Based Company Has Invested $2M to Manufacture 24M Gowns Annually

Petoskey, Mich. – May 1, 2023 – Petoskey Plastics recently installed a new manufacturing line specifically designed to make disposable gowns for the healthcare industry. The company has invested approximately $2 million in engineering and first phase of the project. Additional lines and automation are in their final design stages.

Mike Barto, Vice President of Sales, stated, “We have worked hard to engineer and design a high-speed production line to produce high-quality gowns at globally competitive prices.”

The company’s FDA-registered facility located in Petoskey, Mich. has allocated 10,000 square feet to gown production. Initial capacity will be two million gowns per month. With plans to install a second machine in 2024, capacity will double. Barto said, “We look forward to further ramping up our gown production over the next few years in support of our customers’ demand.”

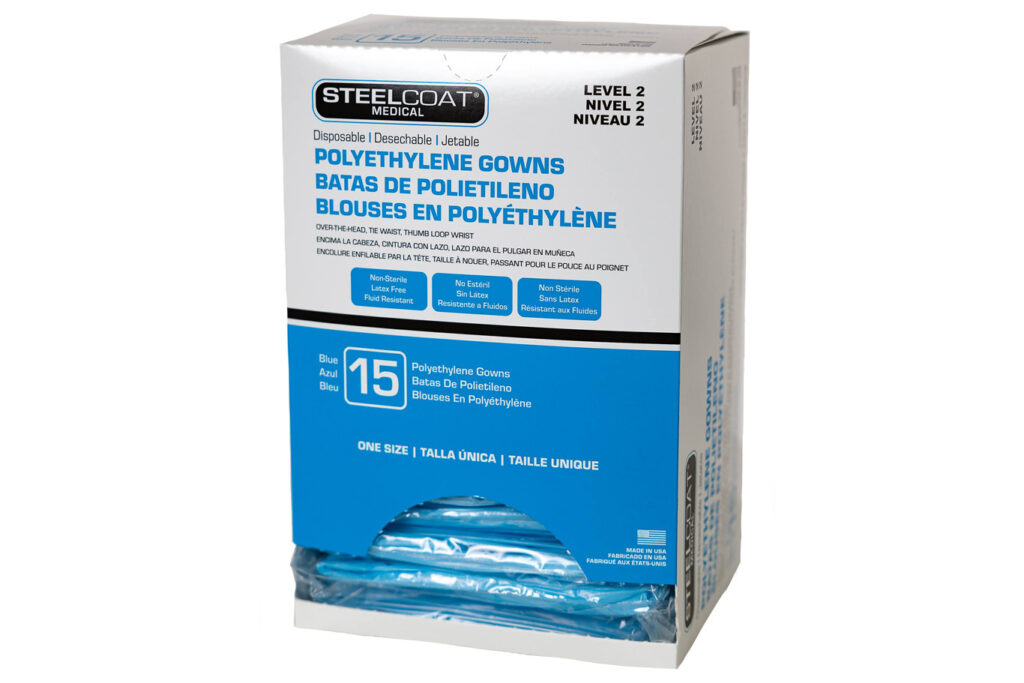

Petoskey Plastics first manufactured gowns on converted automotive OEM lines in March 2020 at the onset of the COVID-19 pandemic. The company made and shipped over five million gowns for 13 Michigan hospitals and multiple hospitals nationwide. Three years later, the gown design has evolved from a 32-pound industrial 200-count roll to individually folded and bagged gowns in a 15-count dispensing box weighing less than 2 pounds.

Consulting with local healthcare workers during the design process allowed Petoskey Plastics to optimize the gown design with usage and safety in mind. The new gown is individually bagged for added protection. Thumb loops prevent sleeve slide and offer maximum arm coverage. An open and perforated tear back offers breathability and quick tear-off removal. A long waist tie fits all sizes and ensures a secure fit. The film features a textured finish for quick and easy unfolding.

Matt Keiswetter, Packaging Division Manager, stated, “After quickly converting our automotive equipment to support the nationwide medical gown shortage in 2020, it was clear North America needed a competitive domestically manufactured secure source. We are very excited to announce the start-up of our newest engineered investment, a high-speed automated gown machine.”

Veteran-owned Petoskey Plastics is the only domestic manufacturer with a high-speed machine dedicated to producing polyethylene gowns. Domestic raw materials, which are Berry and TAA compliant, are extruded in-house to make 3-layer medical grade LLDPE blown film to be converted on the new gown line.

Gown production adds ten new job openings, from packers to operators, to the northern Michigan plant. The company is building operating skills among incumbent and new operators. After the second gown line is installed in 2024, workforce will increase to 25 total packers and operators.

Petoskey Plastics’ gown is FDA-registered as a Class 1 Medical Protection Gown, giving functional protection from fluids in medical facilities and anywhere protection is needed to reduce the risk of contamination. Gowns are sold through distribution under their brand Steelcoat Medical® and available for private label. “Full-sleeve disposable polyethylene gowns made in the USA are now available exclusively at Petoskey Plastics,” Keiswetter said.

Petoskey Plastics is an environmentally focused recycler and plastic film, bag, and resin manufacturer. Headquartered in Petoskey, Michigan, the company provides products and engineered solutions for a variety of industries including automotive, industrial, institutional, retail, construction, home improvement, and medical. Petoskey Plastics has facilities in Michigan, Indiana, Tennessee, and Texas. Learn more about the company at www.petoskeyplastics.com and current job openings here.

Link to Word Document